Why Choose Our Weighing Scale Weights

Troemner offers the most comprehensive selection of scale weights and test weights. Our weight selection includes every imaginable size, class, and type from 5,000 lb. weights to the precise 1 mg weights. Troemner’s portfolio of weights for scales includes our stainless-steel and cast iron weights that exceed the exacting requirements of ANSI/ASTM E617.

In this article, we will focus on ASTM Class 5, Class 6, and Class 7 scale weights and test weights. These scale and test weights are typically used for routine testing and calibration of industrial weighing scales including shipping scales, bench scales, counting scales, floor scales, portioning scales, and other similar products.

Scale weights and test weights are ideal for testing commercial weighing devices and may be used to test most accuracy Class III scales and Class IIIL or IIII scales. Scale weights, test weights and test weight sets are available in ASTM Class 5, Class 6 (replaces NIST F weights), and Class 7. Troemner also offers ASTM Class 4, Class 5 and Class 6 Heavy Capacity Stainless Steel Eyebolt Style Weights.

If you are looking for ASTM Class 1 to 4, explore our Balance Calibration Weights. These classes are typically used for routine testing and calibration of analytical balances and other laboratory balances as well as calibration of other weights.

Types of Weights for Scales We Offer

Accuracy of industrial weighing scales can change over time because of wear, environmental conditions, and other unseen circumstances. Routine testing with scale weights and test weights allows you to confirm the weighing scale is providing accurate results between calibrations. They are essential for this routine check of industrial weighing scales including shipping scales, bench scales, counting scales floor scales and portioning scales. Through a series of measurements, scale weights and test weights are used to ensure scales are providing dependable and accurate readings. Industries such as food, beverage, pharmaceutical, nuclear and chemical rely on scale weights and test weights to check weighing devices in their routine operations.

Each scale weight has specific characteristics defined by the internationally recognized weight standard ANSI/ASTM E617, Standard Specification for Laboratory Weights and Precision Mass Standards. The class of the weight is a key characteristic with a stated maximum permissible error, also known as tolerance or accuracy of the weight.

The general recommendation is the accuracy of the scale weight or test weight should be at least equal to 1/3 the readability of the balance or scale. Therefore, the readability of the weighing device determines the precision of the scale weight or test weight. A review of the weight standard then identifies the weight class that is necessary for the scale weight or test weight for a particular balance or scale.

Accreditation

Accreditation is the independent evaluation of conformity against recognized standards to conduct specific activities to ensure impartiality and competence. Through the application of national and international standards, governments, procurers, and consumers can have confidence in the calibration and test results, inspection reports and certifications provided.

For calibrated weights, accreditation ensures all mass laboratories are playing by the same rules to perform calibrations. All Calibration Laboratories must meet the requirements of the same standard with an external third party making sure the rules are followed.

International Standards

ISO - International Organization for Standardization

ISO is the world’s largest developer of voluntary International Standards. International Standards give state of the art specifications for products, services, and good practices. ISO is an independent, non-government organization that develops the standards through global consensus practices.

ISO/IEC 17025 – General Requirements for the competence of testing and calibration laboratories

ISO/IEC 17025 specifies the general requirements for the quality and competence to conduct tests and/or calibrations and delivering consistent, reliable results. It is applicable to all organizations performing tests and/or calibrations.

NVLAP – National Voluntary Laboratory Accreditation Program

NVLAP (National Voluntary Laboratory Accreditation Program (NVLAP) | NIST) falls under the guidance of NIST (National Institute of Standards and Technology (nist.gov )), part of the U.S. Department of Commerce. NVLAP accreditation audits ensure a calibration laboratory’s compliance to ISO/IEC 17025 and NIST Handbook 150. This independent, third party assessment ensures the science of measurement and laboratory processes are sound and consistently followed.

Troemner ISO 17025 Certificate

Troemner NVLAP Scope of Accreditation to ISO/IEC 17025:2017, NVLAP Lab Code 105013-0

International Weighing Scale Weights Standards

ANSI/ASTM E617, Standard Specification for Laboratory Weights and Precision Mass Standards

Troemner test weights and scale weights are available in ANSI/ASTM E617 Class 5, Class 6, and Class 7. Troemner also offers Heavy Capacity Stainless Steel Eyebolt weights in ASTM Class 4, Class 5 and Class 6. These test weights and scale weights meet or exceed specifications as defined in the standard.

In the ANSI/ASTM E617 standard, the weight specifications are designed so the requirements for surface finish, markings, construction, material density and magnetic properties become more restrictive as weight tolerances decrease to enable the weight to maintain its tolerance over time. The tolerances for the various classes are established in a manner that enables the weights of higher classes to calibrate weights of the next lower class.

NIST Handbook 105-1, Specifications and Tolerances for Field Standard Weights

The specifications and tolerances for reference and field standard weights now directs the user to follow ASTM E617 and OIML R111 requirements. NIST Class F is now a historical class and no longer used in the industry.

As stated in the 2019 Abstract for this standard, “These specifications and tolerances establish the minimum requirements for Field Standards used by State and local weights and measures officials and others in the regulatory verification of weighing devices used in quantity determination of commodities sold by weight. Non-Weights and Measures users may find this handbook helpful in the design of field standard weights, but the requirements should not be considered mandatory for special applications outside of the scope of regulatory weights and measures. The Handbook 105 series of publications are the specifications and tolerances for reference standards and field standards used in weights and measures (legal metrology) applications. This Handbook 105-1 is the first in the series and is specific for the application of weights used for testing scales for compliance to NIST Handbook 44, Specifications, Tolerances, and Other Technical Requirements for Weighing and Measuring Devices.”

H017 Handbook 105 whats new (nist.gov)

Specifications and Tolerances for Reference Standards and Field Standard Weights and Measures, Specifications and Tolerances for Field Standard Weights (2019 Ed) | NIST

Shop ASTM Class 5 to 7 Weights for Scales

Scale Weight and Test Weight Styles and Construction

ASTM Class 5 and Class 6 Stainless Steel Test Weights and Test Weight Sets

Shop Class 5-6 Cylindrical and Grip Handle Stainless Steel Test Weights (Individual)

Shop Class 5-6 Cylindrical and Grip Handle Stainless Steel Test Weight Sets

Stainless Steel Test Weights are primarily used to test commercial weighing devices by State and local weights and measures officials, device installers, and service technicians.

Stainless Steel Cylindrical Weights are legal for trade, which means their design meets NIST Handbook 105-1 that now uses the specifications of ASTM E617 and OIML R111. These weights are approved to be used on legal for trade devices within the United States. Adjusting cavities are typically on the top of the weight and must be tamper resistant.

Troemner’s Stainless Steel Test Weights are available in a variety of styles including flat weights, cylindrical weights, cube weights, and stackable grip handle weights. Troemner’s Stainless Steel Test Weights are manufactured from grade 303 stainless steel alloy that possesses closely controlled density, low magnetic susceptibility, good stability, and resistance to corrosion and handling damage. All surfaces have a satin finish and conform to ASTM specifications for the Class.

- Weights 200 g, 8 oz, 0.5 lb, or 5 ozt and larger have two-piece construction which indicates that the weight is constructed of multiple pieces of raw material. This means that the weight body is constructed from one piece of material with an adjusting cavity. This cavity contains the adjusting material, which is typically the same material from which the weight is made. Once the weight is adjusted into tolerance, it is sealed using an aluminum cap and stainless steel back-up spacer.

- Cylindrical weights smaller than 200 g, 8 oz, 0.5 lb or 5 ozt are one-piece construction, which means the weight is manufactured from a single uniform piece of raw material. One-piece Stainless Steel Test Weights of this size are adjusted by polishing material off the bottom of the weight.

- Weights 10 GN - 2 GN and 0.05 ozt - 0.005 ozt are flat stainless steel with a side of the weight turned up for easy handling.

- 500 mg - 1 mg weights are flat aluminum with a side of the weight turned up for easy handling.

ASTM Class 7 Economical Stainless Steel Weights and Weight Sets

Economical Steel Test Weight Style (Class 7)

Shop Class 7 Cylindrical Stainless Steel Individual Scale Weights

Shop Class 7 Cylindrical Stainless Steel Scale Weight Sets

Troemner Economical Stainless Steel Weights and Weight Sets are quality weights available from 1 mg through 2000 g. Weight Sets are designed to achieve any total mass by combining smaller masses. The makeup of Economical Stainless Steel Weight Sets varies. Weights are adjusted to tolerances specified by ANSI/ASTM E617 Class 7.

Cylindrical Weights 1 g and above are carefully manufactured from stainless steel and are cylindrical in shape for easy gripping. Weights 1 g to 100 g are of one-piece construction and are adjusted during manufacture by removing material from the bottom of the weight. Weights 200 g through 2 kg have an adjusting cavity on the top that is sealed with a plug. Economical Stainless Steel Weights 1 g and above are perfectly flat on top to stack easily on center.

Weights 500 mg and lower are made of stainless steel or aluminum and are flat, one-piece construction with a side turned up to make them easy to handle with forceps. 500 mg and 200 mg weights are made of stainless steel while weights 100 mg and below are made of aluminum. All surfaces are satin finish and conform to specifications in ANSI/ASTM E617. All Economical Stainless Steel weights regardless of design are marked with their nominal mass value.

ASTM Class 5 and Class 6 Cast Iron Heavy Capacity & Grip Handle Scale Weights

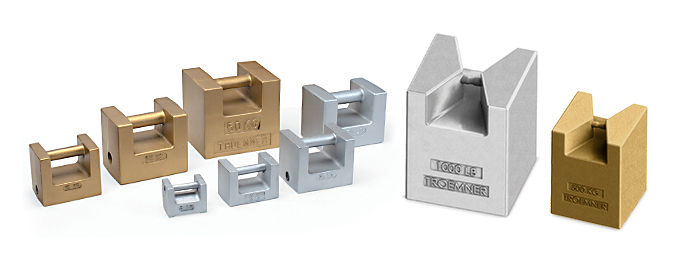

Cast Iron Heavy Capacity Scale Weight Style (Class 5 and Class 6)

Shop Cast Iron Scale Weights

Troemner’s Cast Iron Weights are manufactured to meet NIST Handbook 105-1 that now points to ASTM E617 and OIML R111 standards. The weights are manufactured from high quality iron that meets the specifications for hardness. Castings are free of cracks, pits and sharp edges and meet surface roughness requirements.

Each weight has an adjusting cavity located on its side. Adjusting cavities are sealed with a lead plug and steel back-up spacer to provide a tamper resistant seal of the adjusting cavity. Weights 50 kg/100 lb. and below are designed with a grip-handle for easy transfer. Weights above 50 kg/100 lb. have a slot designed for lifting with a hook.

All surfaces are smooth and free of scratches, dents and pores, and are protected by a durable coat of paint to prevent the casting from rusting. Paint is hard and resistant to chipping. Color coding – gold for metric and silver for avoirdupois – is used to differentiate the weights. Troemner Cast Iron Grip Handle Scale Weights are adjusted to ASTM Class 5 and Class 6.

ASTM Class 4, Class 5 and Class 6 Stainless Steel Heavy Capacity Scale Weights

Stainless Steel Heavy Capacity Scale Weight Style

Shop Heavy Capacity Stainless Steel Weights

Troemner’s Stainless Steel Heavy Capacity Scale Weights are an ideal solution for the food, beverage, pharmaceutical, nuclear, and fine chemical industries. Manufactured from stainless steel, these weights are highly stable and resistant to corrosion – ideal for wash down environments and as a replacement for cast iron weights.

Troemner’s Stainless Steel Heavy Capacity Scale Weights are manufactured from a stainless steel alloy which possesses closely controlled density, low magnetic susceptibility, good stability and resistance to corrosion. Weights range from 20 kg/50 lb. and up, are cylindrical in shape, and have a secure eyebolt on the top center of the weight to allow them to be moved easily with various types of industrial equipment.

Troemner’s Stainless Steel Heavy Capacity Weights have two-piece construction that allows the weights to be adjusted. Within each weight there is a cavity below the eyebolt that is filled with adjusting material, typically the same material from which the weight is made. This cavity is sealed during the production process to ensure the stability of the weight. The eyebolt has an opening of 1½ inches (3.8 cm). All surfaces have a satin finish and are smooth and free of scratches as outlined in ANSI/ASTM E617.

Stainless Steel Heavy Capacity Weights are adjusted to ANSI/ASTM E617 Class 4, Class 5, and Class 6.

Scale Weight and Test Weight Materials

Cast Iron

High quality iron with a consistent density of 7.20 g/cm3 is used in the production of Troemner’s Cast Iron Grip Handle Scale Weights. The castings meet the ASTM E617 surface roughness requirements where the surfaces are smooth and free of scratches, dents and pores. These weights are protected by a durable coat of paint to prevent the casting from rusting. Paint is hard and resistant to chipping. Color coding – gold for metric and silver for avoirdupois – is used to differentiate the weights.

Troemner Cast Iron Grip Handle Scale Weights

- ASTM E617

- Class 5 and Class 6

- Nominal Values 2 kg – 1,000 kg / 5 lb. – 5,000 lb.

303-304 Stainless Steel

303-304 Stainless Steels are used in the production of Troemner’s Scale Weights, Test Weights, Economical Weights and Stainless Steel Heavy Capacity Weights. These grades of stainless steel are general-purpose materials and widely used in many industries. The resistance to corrosion and consistent density at 7.85 g/cm3 of 303-304 Stainless Steels meet the requirements in ASTM E617 for the manufacture of weights.

Troemner Test Weights and Economical Weights manufactured with 303 Stainless Steel are:

- ASTM E617

- Class 6 and Class 7

- Nominal Values 1 g and larger

Troemner Stainless Steel Heavy Capacity Scale Weights manufactured with 303-304 Stainless Steel are:

- ASTM E617

- Classes 4, 5, 6

- Nominal Values 20 kg – 1,200 kg / 50 lb. – 5,000 lb.

5052 – H32 Aluminum

5052 – H32 Aluminum is an alloy that is used at Troemner for our 1 mg to 500 mg Test Weights and Economical Weights. This material can be found in a variety of applications throughout many industries. This material is corrosion resistant and has a consistent density of 2.7 g/cm3 meeting the requirements in the ASTM E617 standard for milligram weights.

Scale Weight Styles, Classes, and Typical Markets

Weight Style | ASTM | Suggested Markets |

Test Stainless Steel Weights | ASTM Class 5, 6 | Primarily used to test commercial weighing devices by state and local weights and measures officials, device installers, and service technicians |

Economical Stainless Steel Weights | ASTM E617 Class 7 | Educational markets |

Cast Iron Grip Handle Scale Weights | ASTM E617 Class 5, 6, 7 | Primarily used to test commercial weighing devices by state and local weights and measures officials, device installers, and service technicians. |

Stainless Steel Heavy Capacity Weights | ASTM E617 Class: 4, 5, 6 | Food, Beverage, Pharmaceutical, Nuclear, Chemical Industries |

Nominal Value Ranges

Troemner offers an extensive selection of individual test weights, scale weights and weight sets that meet the requirements of ANSI/ASTM E617. Whether you need just one weight or a full set, Troemner has precisely what you need to ensure the accuracy of your scales and balances.

ASTM E617 Class | Individual Weights | Weight Sets |

4 | Stainless Steel Heavy Capacity Scale Weights |

|

5 | Stainless Steel Test Weights | Stainless Steel Test Weights |

6 | Stainless Steel Test Weights | Stainless Steel Test Weights |

7 | Economical Stainless Steel Weights | Economical Stainless Steel Weights |

Troemner Scale Weights and Weight Sets are available with certificate options:

- ISO/IEC 17025 Accredited Certificate

- Traceable/Non-Accredited Certificate

- No Certificate

FAQ's

What should I keep in mind when selecting Test Weights and Scale weights?

Several classes, shapes, styles, construction, materials, and sizes are available to meet your needs.

Selecting the proper Test Weight or Scale Weight for your application can be confusing given the number of weight classes, designs, and materials available. The following information can help in your weight selection process.

The following issues need to be considered when selecting weights:

1. Application Accuracy

The correct weight for an application should be more accurate than the precision of the weighing device and must be more accurate than the required precision of your measurement result. It is recommended that a weight have an accuracy that is one-third of the measurement device readability and/or your measurement accuracy requirement.

2. Environment

Temperature and humidity can impact the stability of weights. We recommend stainless steel weights for applications in environments that have excess moisture. Stainless steel weights are much less prone to physical change as compared to cast iron.

Cleanliness of the environment can impact how stable your weights will be over time. Environments with excessive airborne matter, such as dust, can impact the stability of weights. The smoother the surface of a weight, the easier it is to see foreign matter so it can be removed.

3. Reported Uncertainty on Calibration

The uncertainty reported on a calibration is just as important as the measured value itself. The uncertainty provides the statistical confidence that a laboratory has on its calibration process. The larger the uncertainty, the less confidence in the measured value. Note that a measured value added to its associated uncertainty must be less than the tolerance for the weight to be considered within class tolerance.

Learn more about weight uncertainties at https://www.troemner.com/calibration-uncertainty and weight tolerances at https://www.troemner.com/reference-center/weights-reference-center/calibration-weight-tolerance.

4. Certification

Troemner offers a variety of calibration certificates to meet your specific needs for certified scale weights for calibration. Certificates are described in detail at https://www.troemner.com/certificate-options.

5. Special Design or Construction

Troemner manufactures a variety of special application weights, such as weights with hooks or weights that can be stacked on a hanger to build up the total weight. Keep in mind that if you do not see what you need, please contact a Troemner Sales Representative to discuss your special weight requirements.

6. How Often Should I Have My Weights Calibrated? Why? Are There Any Regulations and/or Standards Pertaining to Calibration Intervals?

Troemner recommends that if you use your weights infrequently to moderately, you should have them recalibrated once a year. Weights used frequently or several times a day, should be calibrated once every six months.

Although there are no standards or regulations that specifically address recalibration intervals, this is the industry norm to ensure that these standards are still within their specified tolerances. It is not unusual to see significant “as found” failure rates on those weights that are not recalibrated on an annual basis.

Have other specifics questions, explore additional FAQs in the Weights Reference Center or for more general questions, explore the complete list of FAQs